Trapezoidal sheet metal. Uses and characteristics.

Trapezoidal steel sheet, also known as trapezoidal sheet metal, is a versatile and cost-effective solution commonly used in construction and industrial applications. Its durability and ease of installation make it a popular choice for roofs and facades. In this article, we'll explore the definition, characteristics, and various uses of this essential component in the construction industry.

What is trapezoidal sheet metal?

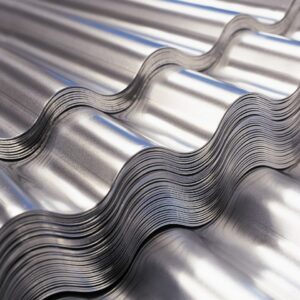

The trapezoidal sheet metal, also known as trapezoidal steel sheet, is a type of roofing and cladding material characterized by its distinctive trapezoidal shape. It is commonly used as an economical and durable solution for covering roofs and facades in various types of buildings and industrial facilities.

The trapezoidal sheet metal It is available in a variety of materials, with the most common options being pre-coated or galvanized steel. This versatile and durable material is a popular choice in the construction industry, offering a number of practical advantages for various building projects.

One of the main characteristics of trapezoidal sheet metal is its robustness, which makes it an essential component in the construction and industrial sectors. Its durable nature and ability to withstand external elements, such as harsh weather conditions and exposure to environmental factors, make it a reliable and long-lasting option for building exteriors.

Furthermore, it is lightweight, which not only makes it easy to handle and install, but also contributes to its suitability for a wide range of construction and renovation projects.

Characteristics

Trapezoidal sheet metal is known for its versatility and practical characteristics, making it a popular choice for construction and cladding applications. It offers excellent resistance to corrosion and oxidation, ensuring it maintains its structural integrity and aesthetic appeal for a long time.

Furthermore, its lightness, combined with its high durability, contributes to its ease of installation and long-term performance, providing a reliable and cost-effective solution for roofing and cladding needs.

In addition to its physical properties, trapezoidal sheet metal is available in a variety of colors, finishes, and surface textures, allowing for a high degree of customization to meet specific aesthetic and design requirements. This versatility in appearance, combined with its practical advantages, makes it a sought-after material for both functional and decorative applications in the construction industry.

Uses in construction

Trapezoidal sheet metal is widely used in construction for a variety of practical purposes, such as roofing, cladding, and enclosure systems. Its adaptability and strength make it suitable for a variety of applications, including industrial buildings, warehouses, agricultural facilities, and residential structures.

In addition to traditional construction projects, trapezoidal sheet metal is also used for architectural elements, canopies, and awnings, demonstrating its versatility and great utility in the built environment.

Furthermore, the material's ability to provide an effective barrier against external elements, along with its thermal and acoustic insulation properties, increases its value in construction, contributing to the creation of comfortable and functional built environments. Whether used in industrial, commercial, or residential construction, trapezoidal sheet metal is a reliable and practical choice for a wide variety of structural and design applications.

Roofs and Facades

The trapezoidal sheet metal It is a preferred choice for both roofing and façade systems, offering a seamless and aesthetically pleasing solution for the exterior envelope of buildings. Its application on roofs provides a protective and weather-resistant covering, while its use on façades contributes to the creation of visually appealing and durable exteriors.

The possibility of using trapezoidal sheet metal on both roofs and facades highlights its versatility and its importance in ensuring the structural integrity and aesthetic quality of buildings.

In addition, the use of the Trapezoidal sheet metal on roofs and facades allows the application of efficient and cost-effective construction solutions., which meet the functional and design requirements of a wide range of architectural typologies and styles. Whether in the form of traditional trapezoidal profiles or custom-designed elements, trapezoidal sheet metal plays a vital role in creating modern, durable, and visually striking building exteriors.

In the Industry

Within the industrial sector, trapezoidal sheet metal is an integral part of building construction, particularly for waterproofing and cladding applications in industrial facilities, factories, and logistics centers. Its use in industrial environments is attributed to its ability to provide a reliable and durable enclosure., offering protection and structural support to a wide variety of operational and storage spaces. Trapezoidal sheet metal's compatibility with industrial environments, along with its resistance to mechanical stress and environmental factors, positions it as a practical and reliable material for industrial construction needs.

Furthermore, trapezoidal sheet metal contributes to the overall efficiency and functionality of industrial buildings, creating safe and productive work environments while meeting the industry's structural and regulatory requirements. Its effectiveness in withstanding the demands of industrial operations, combined with its ease of installation and maintenance, solidifies its position as the preferred choice for roofing and cladding in industrial construction.

Comparison with the mini wave plate

When comparing profiled sheet metal with corrugated sheet metal, it's important to note that both materials offer unique advantages and applications in construction. While trapezoidal sheet metal is characterized by its distinctive trapezoidal profiles, corrugated sheet metal is defined by its repetitive wave pattern with symmetrical grooves. In terms of structural performance, The shape of the trapezoidal sheet metal provides greater strength and load capacity, making it suitable for covering greater distances and supporting heavier loads compared to corrugated sheet metal.

In addition, the design and The trapezoidal sheet metal profile contributes to effective water drainage. and greater weather resistance, which further distinguishes it from corrugated sheet metal in terms of applications and performance in different climatic conditions.

Both trapezoidal and corrugated sheet metal offer insulation and protection benefits, and the choice between one or the other depends on specific project requirements, design preferences, and performance criteria for the intended application.

Dimensions and thicknesses

Trapezoidal sheet metal is available in a range of standard dimensions and thicknesses to suit various construction and design requirements.

The usual thicknesses of trapezoidal sheets usually range between 0.6 and 1 mm, offering flexibility in structural performance and load capacityThe standard widths and lengths of trapezoidal sheets offer options for different roof spans, facade dimensions, and cladding configurations, enabling customized solutions to meet specific project needs and design intentions.

In addition to standard dimensions, custom sizes and thicknesses can also be manufactured to meet the unique specifications of each project, providing greater adaptability and versatility in the use of trapezoidal sheets in a wide range of architectural and construction applications.

Installation of the trapezoidal sheet

Installing trapezoidal sheets is a simple process that can be carried out effectively with the proper knowledge and techniques. The sheets are typically installed with specified distances between supports, ensuring structural integrity and load distribution throughout the roofing or cladding system.

The ease of installation, combined with the material's lightness and ease of handling, contributes to efficient and timely project execution, making it a practical choice for construction professionals and contractors.

Due to its lightness, The installation of trapezoidal sheets can be carried out with minimal effort and material., offering a cost-effective and time-saving solution for construction projects. The use of standard fastening and fixing methods, along with the necessary accessories to secure the sheets in place, facilitates a systematic and reliable installation process, resulting in a durable, high-performance roofing and cladding system.

Conclusion

In conclusion, trapezoidal steel sheet is a versatile and durable solution commonly used in the construction industry for roofing and facade applications. Its unique shape and variety of sizes and thicknesses make it suitable for a wide range of projects. With its easy installation and cost-effectiveness, it has become a popular choice for both new construction and renovation projects.

Trapezoidal sheet metal is a product derived from trapezoidal sheet metal, which is used for the manufacture of roofs and facades.